Sterilization is an essential process in many industries, especially in healthcare, veterinary medicine, and manufacturing, to ensure the safety of equipment, tools, and products. One of the most effective sterilization methods for delicate and complex items is ethylene oxide sterilization (EO sterilization). Ethylene oxide is a colorless sterilant with strong antimicrobial properties, capable of eliminating bacteria, viruses, fungi, and spores from a variety of materials.

What makes ethylene oxide sterilization unique is its ability to work at low temperatures and penetrate deeply into hard-to-reach areas. This makes it ideal for items that cannot withstand the high heat or moisture required for other sterilization methods, such as autoclaving. By using ethylene oxide, industries can ensure the sterility of their products without compromising their integrity.

Ethylene oxide gas is particularly beneficial in fields that require high levels of sterility, such as healthcare, pharmaceuticals, and food packaging. It is also commonly used for sterilizing medical devices and instruments that are sensitive to heat or moisture. If you’re looking for a reliable sterilization method, read on to discover how ethylene oxide can meet your needs and maintain product sterility across various industries.

Key Takeaways

- Ethylene oxide sterilization is an effective method for sterilizing a wide range of materials, including plastics, rubbers, metals, textiles, and electronics, without causing damage from heat or moisture.

- It is commonly used for medical devices, such as surgical instruments, implants, catheters, and diagnostic tools, that require precise sterilization while maintaining material integrity.

- Factors like material composition, item size, and aeration requirements determine whether ethylene oxide is suitable for specific items, ensuring the process is both effective and safe.

- While ethylene oxide is highly effective, it has limitations, such as the need for proper aeration to remove residual gas and its higher cost compared to other sterilization methods.

Common Materials Compatible with Ethylene Oxide

Ethylene oxide sterilization is a versatile process that can sterilize a wide range of materials. Its ability to work without heat or moisture makes it a popular choice for delicate and sensitive materials, such as:

- Plastics: Many plastics, such as polypropylene, polyethylene, polycarbonate, and polyvinyl chloride (PVC), are compatible with EO sterilization. These materials are commonly used in medical devices and packaging. EO sterilization ensures that these items are free from contaminants while preserving their structural integrity.

- Rubber and Elastomers: Silicone, latex, and other flexible materials are often used for items like medical gloves, catheters, seals, and gaskets. EO sterilization is ideal for these materials, as it maintains flexibility and strength while removing microorganisms.

- Textiles: Surgical drapes, gowns, and masks made from synthetic fibers or fabrics are often sterilized with ethylene oxide. The ability of EO to sterilize without causing degradation or shrinkage is especially important in medical settings where maintaining the integrity of fabrics is essential.

- Electronic Components: EO sterilization is one of the few methods that can safely sterilize electronic devices such as endoscopes, diagnostic tools, and pacemakers. These components may contain sensitive parts that can be damaged by heat or moisture but remain intact during the EO sterilization process.

- Glass and Metal: While glass and metal items are not sensitive to heat, they are often sterilized alongside more delicate items to maintain a consistent level of sterility. Instruments like scalpels and forceps that are made from metal are frequently sterilized with ethylene oxide.

Thanks to its deep penetration, ethylene oxide sterilization can reach every part of these materials, including complex geometries, ensuring a high level of sterility and minimal risk of contamination.

Medical Devices Sterilized with Ethylene Oxide

The medical industry relies heavily on ethylene oxide sterilization to ensure the safety and sterility of critical equipment and devices. Some of the most common medical items sterilized using EO include:

Surgical Instruments:

Scalpel blades, forceps, scissors, and other precision instruments are sterilized with EO to maintain cleanliness and reduce the risk of infection. Since these instruments are often used in sterile environments, ensuring they are completely free from pathogens is essential.

Implantable Devices:

Items such as pacemakers, artificial joints, stents, and dental implants require sterilization without compromising their material properties. Ethylene oxide sterilization is ideal for these sensitive devices, ensuring they are free of contaminants and safe for insertion into the human body.

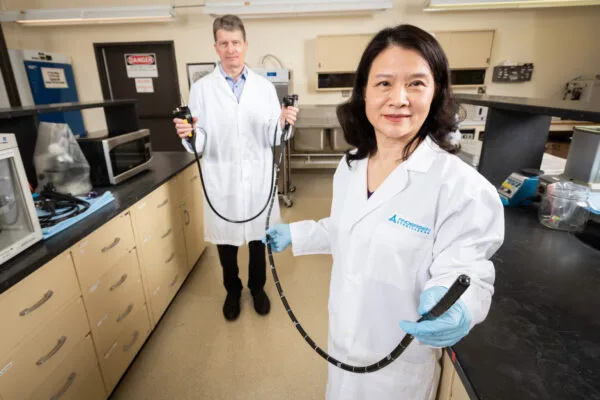

ENDOSCOPES, Catheters and Tubing

Flexible and delicate, these items benefit from EO’s ability to sterilize without deformation or damage. For example, urinary catheters and intravenous tubing need to be sterile to prevent infections, and EO provides a reliable sterilization option for these types of products. Endoscopes, sensors, and other devices used in diagnostic procedures must be sterile to ensure patient safety. Many of these devices are made from complex materials, and EO sterilization ensures that all parts of the equipment are disinfected without causing any harm to the device itself. Andersen’s EOGas 4 is the only system in the world cleared by the FDA to sterilize >1100 mm working lumen length endoscopes. It’s a fact. EOGas 4, featuring award-winning EO-Flexible Chamber Technology, is the first sterilization system to receive FDA 510(k) clearance for terminal sterilization of duodenoscopes and colonoscopes. When you add EOGas EOGas 4 to your infection prevention line of defense, you protect your critically ill patients, preserve your fragile instruments and safeguard your healthcare facility.

Single-Use Medical Supplies:

Disposable items like syringes, bandages, gloves, and IV sets are commonly sterilized using EO gas. Since these items are used only once, ensuring that they remain free from bacteria, viruses, and other harmful microorganisms is crucial to patient safety.

Ethylene oxide sterilization is particularly valuable for items that have intricate designs or are made from a combination of materials, as it ensures thorough sterilization without requiring disassembly.

Factors That Determine Compatibility with Ethylene Oxide

Several factors determine whether an item can be effectively sterilized with EO:

1. Material Composition

Some materials, such as certain foams, natural rubbers, and biodegradable polymers, may absorb ethylene oxide gas or degrade under exposure. It’s essential to verify material compatibility before sterilization to avoid any degradation or unintended changes in material properties.

2. Item Size and Shape

EO sterilization is ideal for items with complex geometries or hard-to-reach areas, as the gas penetrates deeply and ensures uniform exposure.

3. Residual Gas Tolerance

Ethylene oxide gas can remain on sterilized items unless thoroughly aerated. Items that retain residual EO gas require extra care to remove any remaining traces before use. This is especially critical for items used in sensitive applications, such as medical implants.

4. Regulatory Standards

Items must meet specific regulatory guidelines, such as FDA and ISO standards, to be considered safe and effective for EO sterilization.

5. Packaging Requirements

The packaging of items must be carefully selected to allow ethylene oxide gas to penetrate while maintaining sterility after the process is complete. Special sterilization pouches or wraps are often used to ensure effective gas flow during sterilization.

Protect Your Patients Today!

Ethylene oxide sterilization is a critical service for industries that require absolute sterility, particularly in the medical, veterinary, and manufacturing sectors. Its ability to sterilize sensitive materials and complex devices makes it indispensable for ensuring safety and hygiene.

At Andersen Sterilizers, we provide gas sterilization services tailored to your specific requirements. Whether you’re in healthcare, veterinary medicine, or manufacturing, we have the expertise and technology to ensure your products meet the highest sterility standards.

Don’t compromise on safety—partner with us to protect your patients and preserve your instruments. Check out our state-of-the-art sterilizers at sterility.com/products.