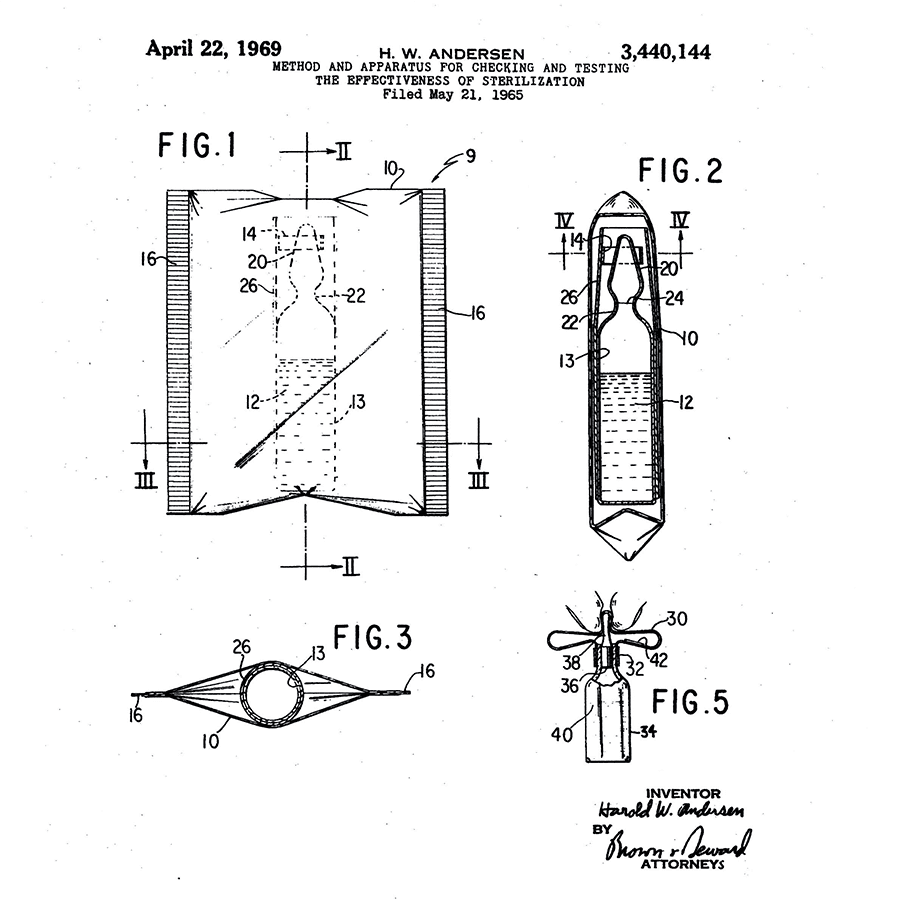

In 1969, H.W. Andersen, M.D., a pioneering figure in medical technology, designed and patented the first self-contained Biological Indicator (BI). This groundbreaking invention, which marked the beginning of an entire industry, revolutionized the process of verifying sterilization effectiveness and has left a lasting legacy in the field of healthcare sterilization.

The Evolution of Sterilization Verification

Before Dr. Andersen’s innovation, the process of verifying sterilization involved the use of spore strips, which were incubated to determine the success of a sterilization cycle. This method, while functional, had several points where cross-contamination could occur, potentially leading to false positives.

Here’s how the process worked: at the end of a sterilization cycle, a technician would open a glassine envelope containing a Bacillus subtilis spore strip. Using sterile forceps, the technician would place the strip into a test tube with nutrient broth and incubate it for at least 48 hours in a warm environment. The many steps in this process introduced risks of contamination, which could compromise the results.

Dr. Andersen’s Innovative Solution

Dr. Andersen’s self-contained Biological Indicator, named “Steritest,” provided a much-needed solution to these challenges. His design included a glass ampoule filled with growth medium and a spore dot, all packaged within a hermetically sealed pouch made of clear plastic and Tyvek. The medium contained a pH indicator dye that would change color if any spores survived the sterilization cycle.

The procedure was straightforward yet effective: after the cycle, the technician would break the ampoule inside the pouch, shake it to mix the medium with the spore dot, and then allow it to incubate in a warm place for 48 hours. The sealed environment of the pouch eliminated the risk of external contamination. If any spores survived the cycle, the growth medium would change color, signaling a failed sterilization.

The Genius of Simple Solutions

A.E. “Ted” May, CEO of Andersen Products, describes Dr. Andersen’s approach as “bringing very simple engineering solutions to nagging everyday problems.” This ability to simplify complex processes was evident in the Steritest, which combined functionality with ease of use, setting a new standard in sterilization verification.

Dr. Andersen further enhanced his invention by adding a Dosimeter to each Steritest. This additional feature acted as an initial “screening test” to confirm that the sterilization cycle met the required time, temperature, and gas concentration parameters.

The Legacy and Impact

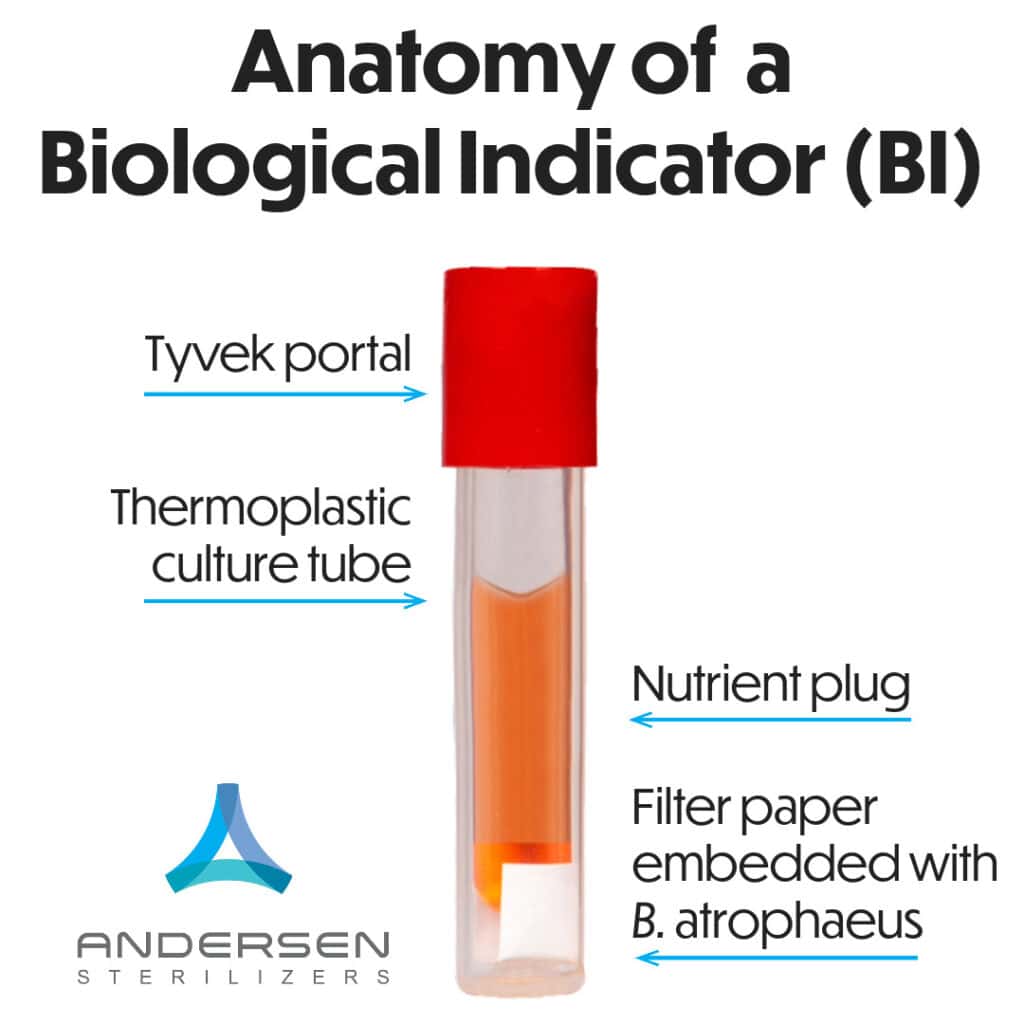

Following the expiration of Dr. Andersen’s patent after 17 years, the landscape of self-contained BIs evolved significantly. Other manufacturers built upon his original concept, developing highly compact devices that combined the nutrient plug and filter paper embedded with Bacillus atrophaneus spores into a thermoplastic culture tube, capped with a Tyvek portal and a color change indicator label.

Dr. Andersen’s foresight in allowing other companies to focus on self-contained BIs led to advancements in production efficiency and cost-effectiveness. Today, numerous companies specialize in the manufacture of these devices, producing them in large quantities and making them more affordable for buyers—an outcome that aligns with Dr. Andersen’s commitment to accessibility and innovation.

A Lasting Legacy

Dr. Andersen’s impact extends beyond his initial invention. With over 80 patents to his name, many of which sparked the creation of entire industries, his contributions to technology and healthcare remain influential. His pioneering work in sterilization verification through Biological Indicators has not only improved safety in medical procedures but also set a benchmark for future innovations in the field.

Dr. Andersen’s legacy is a testament to the power of simple yet effective engineering solutions in addressing complex challenges. His work continues to inspire advancements in sterilization technology and exemplifies the enduring importance of organization and innovation in achieving success.