Emissions Abators

Make it zero emission

Andersen’s emissions abators are designed to remove more than 99% of the ethylene oxide emitted from our sterilizers.

When combined with any Andersen sterilizer, our award-winning gas abatement equipment releases a fraction of a gram of EO per cycle, and less than a pound of total emissions per year, effectively making the process zero emissions. Both abators employ a dry catalyst resin that converts ethylene oxide to biodegradable organic compounds.

Our systems are recognized for using a microdose of ethylene oxide and our emissions fall well below all federal guidelines. If you choose to abate, remember we have this option for you.

Award-winning Innovation

Installation is Quick & Easy

The vent hose from the sterilizer connects to the AN5100 Abator, which is then vented to the outside of the building for extra safety.

The AN5100 Replaceable Cartridge Abator is controlled and monitored through a single wire connection to the sterilizer. Accurate tracking of gas usage will automatically alert the operator when it approaches time to change the cartridge.

Replacement Cartridge

After 200 cycles, the gas abatement equipment will alert the operator that it’s time to change the cartridge. The old cartridge can be disposed of with ordinary waste, if local regulations permit, or it can be returned to Andersen for disposal. The AN5100.00 Replacement Cartridge is available via standard ground shipping.

Note: All AN74j, AN75 and EOGas 4 Sterilizers are abator-ready. AN74i/ix units starting with lot number 243588/243583 (9/14/2004) are abator-ready.

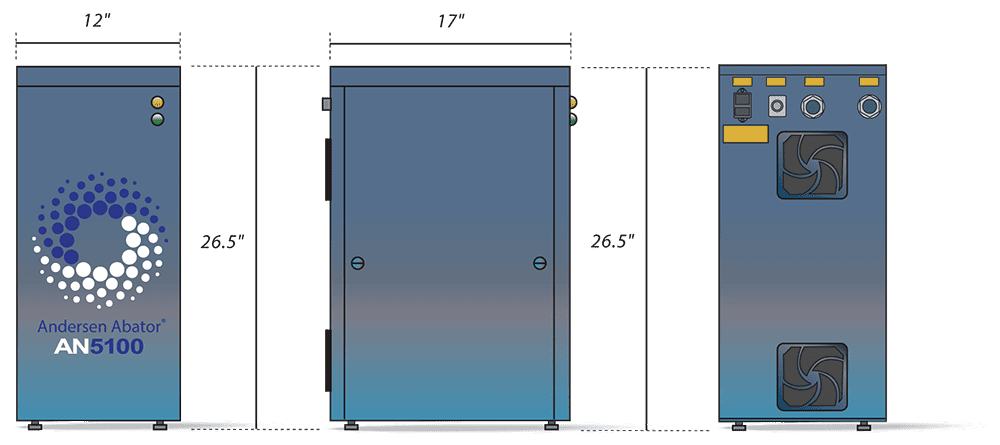

AN5100 Specs

| Dimensions | 17″ L x 12″ W x 26.5″ H |

| Power | 115V, 4 amps or 230V, 2 amps |

| Operating weight | 67 lb |

| AN5100 Abator Order #: | 115V – AN5100.01 230V – AN5100.11 |

| Replacement Cartridge Order #: | AN5100.00 |

| Indoor use | Temperature range 68ºF – 91ºF |

Installation is Quick & Easy

Installation is simple, as the abator easily attaches to new EOGas 3 sterilizers. At time of abator installation, the EOGas 3 extractor must be reprogrammed, requiring Andersen Field Service support.

Replacement Drum

The AN5200 Abator Drum is available via standard ground shipping. It is designed to abate up to 1,800, 10.5g EO gas cartridges before needing to be replaced. Spent drums are non-hazardous and can be disposed of with ordinary waste, if local regulations permit. Drums can also be returned to Andersen for disposal.

Note: If your EOGas 3 sterilizer was built in 2018 or before, we have an alternate abator option for you. Be sure to mention your sterilizer’s age when ordering your abator so it will be compatible.

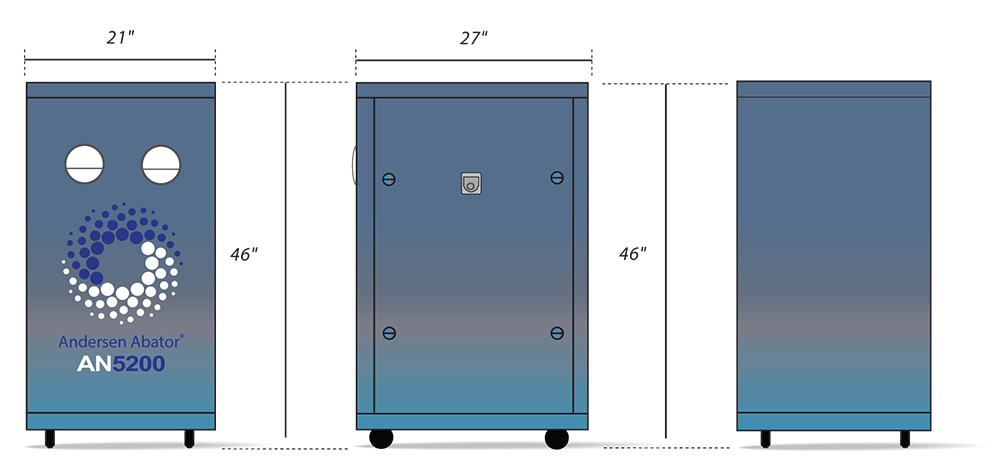

AN5200 EO Abator Specs

| Dimensions | 27″ L x 21″ W x 46″ H |

| Power | N/A |

| Cabinet weight | 100 lb |

| AN5200 Abator Order #: | AN5200.98 |

| Replacement Drum Order #: | AN5200.00 |

| Indoor use | Temperature range 68ºF – 91ºF |

| Altitude | Up to 6,562 feet |

Why Ethylene Oxide (EO/EtO) Sterilization?

Ethylene oxide is the gold standard in sterilization. It offers hospital-level sterility assurance (10⁻⁶) along with

unparalleled gentleness and material compatibility.