Lethal on Pathogens.

Gentle on Instruments.

Andersen’s award-winning EO-Flexible Chamber Technology sets Andersen apart. Removing excess air from the sterilization bag, Andersen’s FDA-cleared sterilizers require less gas to achieve terminal sterilization than any other system on the market. Welcome to EO sterilization reimagined.

Protect Your Patients. Preserve Your Instruments.

We are proud to offer FDA-cleared sterilizers featuring Ethylene Oxide-Flexible Chamber Technology (EO-FCT),

an award-winning solution that sets us apart from conventional rigid chamber systems. Our advanced sterilizers

utilize up to 90% less ethylene oxide than any other system on the market. We invite you to see firsthand

how our reliable technology can safeguard your patients while ensuring the longevity of your instruments.

HEALTHCARE

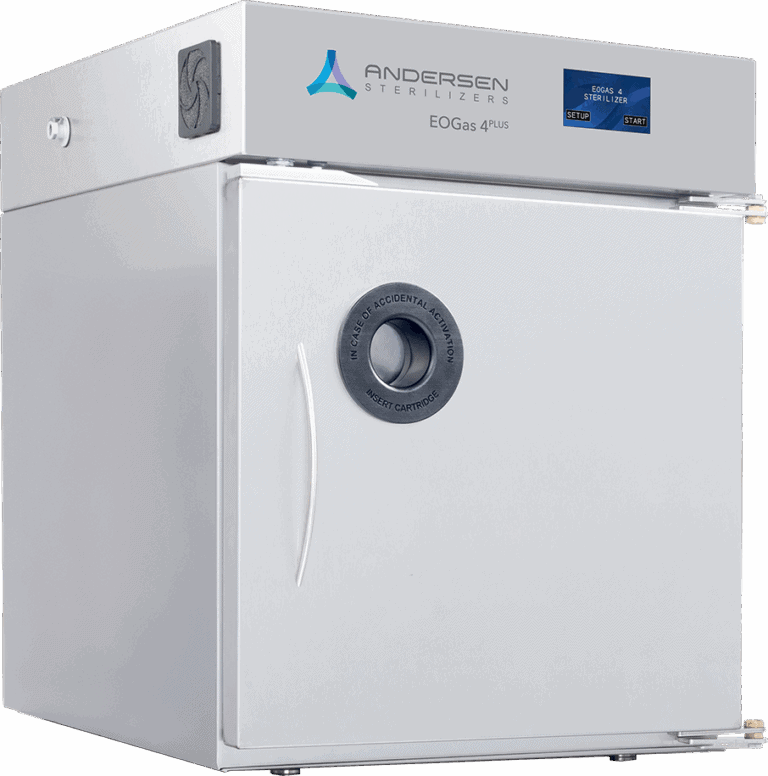

Hospitals require safe, reliable sterilization solutions. Andersen’s newly released EOGas 4PLUS, with EO-Flexible Chamber Technology, is the perfect complement to your infection prevention strategy.

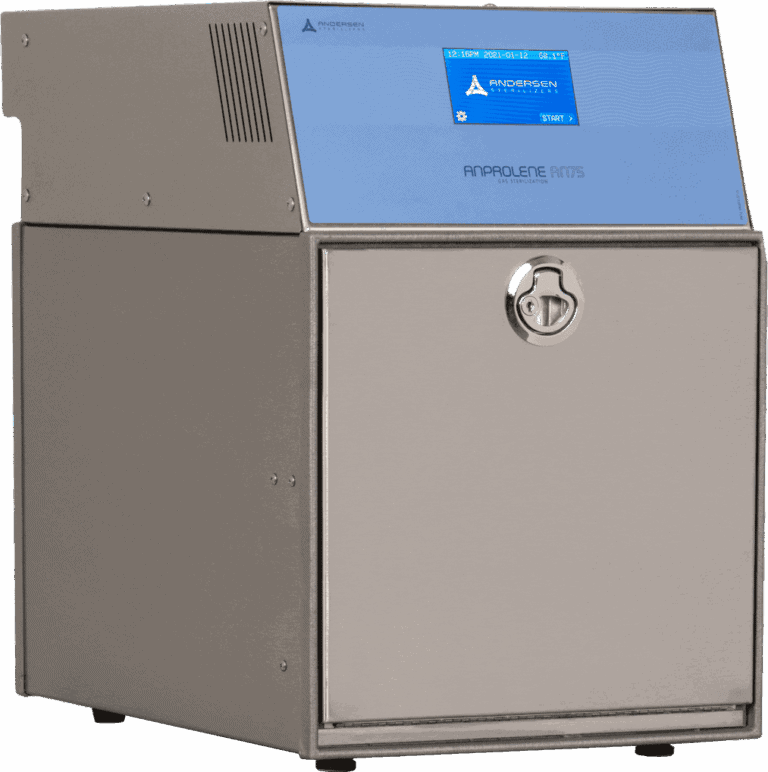

VETERINARY

Low temperature. Low dose. Low emissions. Low per-cycle costs. Enjoy peace of mind with minimal investment. The AN75 systems empower you to safeguard your patients while preserving your instruments.

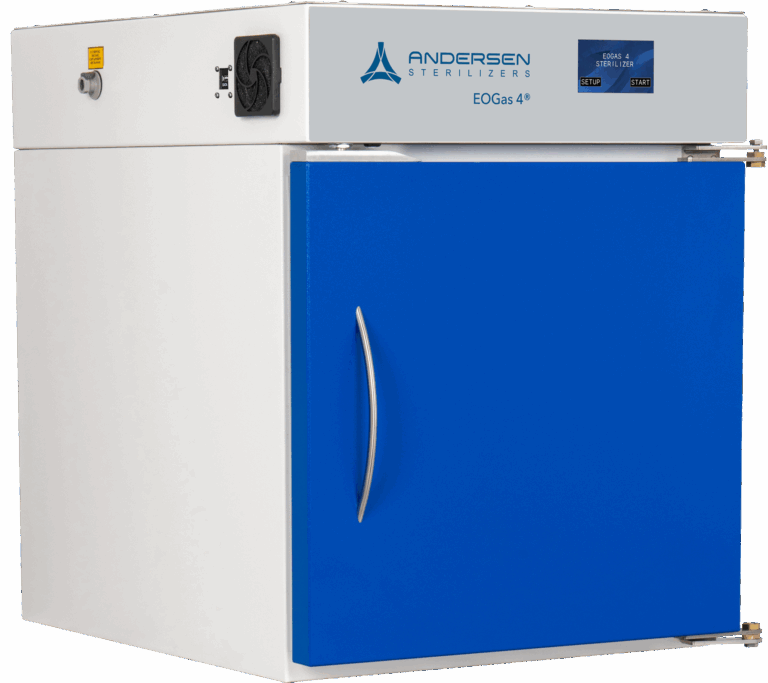

RESEARCH

Andersen’s tabletop sterilizers require just 17.6 grams of EO to achieve terminal sterilization, allowing for a shelf life of up to six months. See how AN75 and EOGas 4PLUS can support your research reprocessing needs.

MANUFACTURING

No matter where you are in the product development process — from research and development to production — Andersen offers in-house and contract sterilization solutions that are sure to meet your specific needs.

Breakthrough Technology

Ethylene Oxide-Flexible Chamber Technology Employs 90% Less EO Than Any Other System of Its Kind

Andersen’s exclusive and award-winning EO-Flexible Chamber Technology removes excess air from a flexible chamber. As a result, our systems require only a microdose of EO to achieve terminal sterilization.

Why Ethylene Oxide?

There are many benefits to ethylene oxide sterilization, some of which may be crucial to your hospital or clinic, especially when reprocessing complex multi-channel endoscopes and delicate medical devices. Andersen’s FDA-cleared sterilizers offer several advantages, including low per-cycle cost, low-temperature operation and EO-Flexible Chamber Technology, which allows our systems to use a microdose of EO — just 17.6 grams per cycle. Our systems are able to achieve terminal sterilization (10-6 SAL) with 90% less EO than our competitors — this is ethylene oxide sterilization reimagined.

FEATURED PRODUCTS

Choose the EO solution that fits your workflow:

Andersen systems, equipped with our innovative EO‑Flexible Chamber Technology®, are expertly crafted to cater to the diverse needs of both

compact clinics and high-demand facilities.

A sterilizer for every scale and clinical setting.

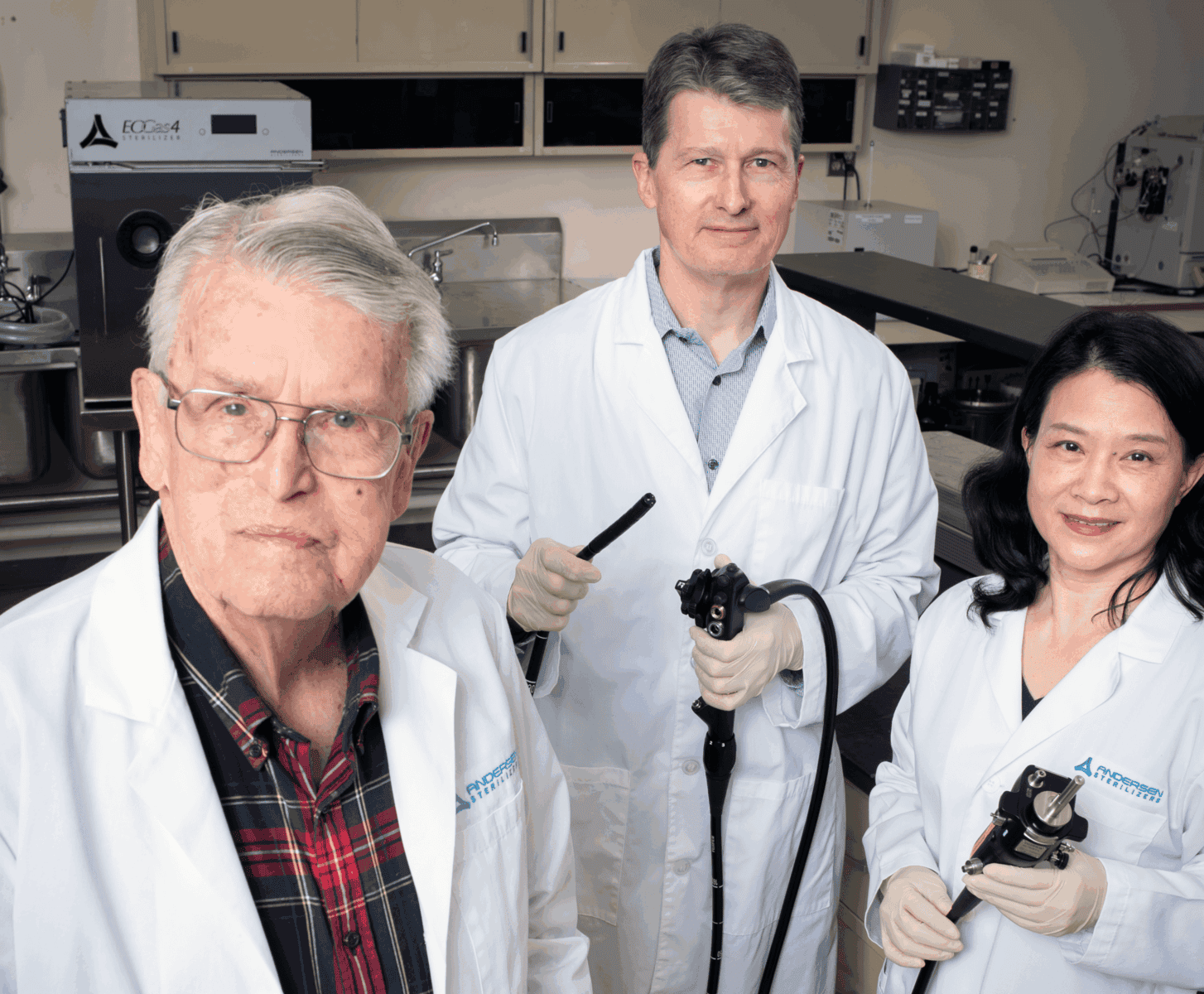

Expert Guidance for Your Needs

Tell us about your sterilization requirements — our experts are here to guide you to the perfect EO solution.